The processing of optical components is divided into hot processing, cold processing and special processing. Cold working is the process of sawing, rough grinding, fine grinding, polishing and centering grinding with abrasive or fixed abrasive. Special machining only changes the properties of polished surfaces, and does not change the shape and size of optical components, including coating, calibration, photography and gluing.

The main tasks of its processes are:

(1) Rough grinding process: making the surface roughness and spherical radius meet the requirements of fine grinding.

(2) Fine grinding process: making the components processed to the specified size and requirements, and preparing for polishing.

(3) Polishing process: making the components surface bright and reach the required optical precision.

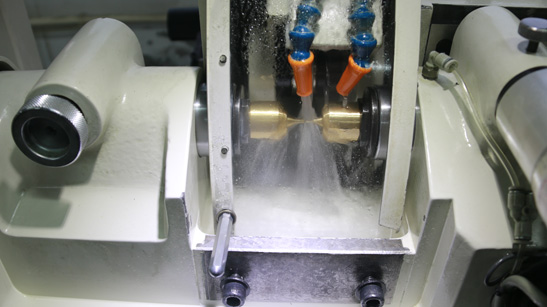

(4) Centering edge grinding process: eliminate eccentricity and make the radial dimension of side cylinder meet the assembly requirements.

(5) Coating process: according to the using requirements, design suitable film for the products.

(6) Gluing process: gluing different optical parts together to make the optical axis coincide or turn in a certain direction.

Workshop production capacity:

Processing size: 0.8-300mm

The machining radius is 0.5mm-plano.

Tel: +86-591-83597829

+86-591-83349016

Fax: +86-591-83300646

Web: www.rising-eo.com

E-mail: sales@rising-eo.com

Add: Bldg 24#, Jinshan Fuwan Industrial Park, No.869, Pan Yu Road, Fuzhou 350002, China

|